There are many uses for fuel cells — right now, all of the major automakers are working to commercialize a fuel cell car. Fuel cells are powering buses, boats, trains, planes, scooters, forklifts, even bicycles. There are fuel cell-powered vending machines, vacuum cleaners and highway road signs. Miniature fuel cells for cellular phones, laptop computers and portable electronics are on their way to market. Hospitals, credit card centers, police stations, and banks are all using fuel cells to provide power to their facilities. Wastewater treatment plants and landfills are using fuel cells to convert the methane gas they produce into electricity. Telecommunications companies are installing fuel cells at cell phone, radio and 911 towers. The possibilities are endless.

Stationary

More than 2500 fuel cell systems have been installed all over the world — in hospitals, nursing homes, hotels, office buildings, schools, utility power plants - either connected to the electric grid to provide supplemental power and backup assurance for critical areas, or installed as a grid-independent generator for on-site service in areas that are inaccessible by power lines.

Fuel cell power generation systems in operation today achieve 40 percent fuel-to-electricity efficiency utilizing hydrocarbon fuels. Since fuel cells operate silently, they reduce noise pollution as well as air pollution and when the fuel cell is sited near the point of use, its waste heat can be captured for beneficial purposes (cogeneration). In large-scale building systems, these fuel cell cogeneration systems can reduce facility energy service costs by 20% to 40% over conventional energy service and increase efficiency to 85 percent. Check out our database of worldwide stationary fuel cell installations.

Fuel cell power generation systems in operation today achieve 40 percent fuel-to-electricity efficiency utilizing hydrocarbon fuels. Since fuel cells operate silently, they reduce noise pollution as well as air pollution and when the fuel cell is sited near the point of use, its waste heat can be captured for beneficial purposes (cogeneration). In large-scale building systems, these fuel cell cogeneration systems can reduce facility energy service costs by 20% to 40% over conventional energy service and increase efficiency to 85 percent. Check out our database of worldwide stationary fuel cell installations.

Telecommunications - With the use of computers, the Internet, and communication networks steadily increasing, there comes a need for more reliable power than is available on the current electrical grid, and fuel cells have proven to be up to 99.999% (five nines) reliable. Fuel cells can replace batteries to provide power for 1kW to 5kW telecom sites without noise or emissions, and are durable, providing power in sites that are either hard to access or are subject to inclement weather. Such systems would be used to provide primary or backup power for telecom switch nodes, cell towers, and other electronic systems that would benefit from on-site, direct DC power supply.

Telecommunications - With the use of computers, the Internet, and communication networks steadily increasing, there comes a need for more reliable power than is available on the current electrical grid, and fuel cells have proven to be up to 99.999% (five nines) reliable. Fuel cells can replace batteries to provide power for 1kW to 5kW telecom sites without noise or emissions, and are durable, providing power in sites that are either hard to access or are subject to inclement weather. Such systems would be used to provide primary or backup power for telecom switch nodes, cell towers, and other electronic systems that would benefit from on-site, direct DC power supply.

Landfills/Wastewater Treatment Plants/Breweries - Fuel cells currently operate at landfills and wastewater treatment plants across the country, proving themselves as a valid technology for reducing emissions and generating power from the methane gas they produce. They are also installed at several breweries - Sierra Nevada, Kirin, Asahi and Sapporo. Untreated brewery effluent can undergo anaerobic digestion, which breaks down organic compounds to generate methane, a hydrogen rich fuel.

Landfills/Wastewater Treatment Plants/Breweries - Fuel cells currently operate at landfills and wastewater treatment plants across the country, proving themselves as a valid technology for reducing emissions and generating power from the methane gas they produce. They are also installed at several breweries - Sierra Nevada, Kirin, Asahi and Sapporo. Untreated brewery effluent can undergo anaerobic digestion, which breaks down organic compounds to generate methane, a hydrogen rich fuel.

Transportation

Cars - All the major automotive manufacturers have a fuel cell vehicle either in development or in testing right now, and several have begun leasing and testing in larger quantities. Commercialization is a little further down the line (some automakers say 2012, others later), but every demonstration helps bring that date closer. Check out our page on Benefits for Transportation and for a comprehensive chart showcasing all the fuel cell vehicles ever demonstrated, visit our Charts page.

Cars - All the major automotive manufacturers have a fuel cell vehicle either in development or in testing right now, and several have begun leasing and testing in larger quantities. Commercialization is a little further down the line (some automakers say 2012, others later), but every demonstration helps bring that date closer. Check out our page on Benefits for Transportation and for a comprehensive chart showcasing all the fuel cell vehicles ever demonstrated, visit our Charts page.

Buses - Over the last four years, more than 50 fuel cell buses have been demonstrated in North and South America, Europe, Asia and Australia. Fuel cells are highly efficient, so even if the hydrogen is produced from fossil fuels, fuel cell buses can reduce transit agencies’ CO2 emissions. And emissions are truly zero if the hydrogen is produced from renewable electricity, which greatly improves local air quality. Because the fuel cell system is so much quieter than a diesel engine, fuel cell buses significantly reduce noise pollution as well. For a comprehensive chart on fuel cell buses, click here.

Buses - Over the last four years, more than 50 fuel cell buses have been demonstrated in North and South America, Europe, Asia and Australia. Fuel cells are highly efficient, so even if the hydrogen is produced from fossil fuels, fuel cell buses can reduce transit agencies’ CO2 emissions. And emissions are truly zero if the hydrogen is produced from renewable electricity, which greatly improves local air quality. Because the fuel cell system is so much quieter than a diesel engine, fuel cell buses significantly reduce noise pollution as well. For a comprehensive chart on fuel cell buses, click here.

Scooters - In spite of their small size, many scooters are pollution powerhouses. Gas-powered scooters, especially those with two-stroke engines, produce tailpipe emissions at a rate disproportionate to their small size. These two-stroke scooters produce almost as much particulate matter and significantly more hydrocarbons and carbon monoxide as a heavy diesel truck. Fuel cell scooters running on hydrogen will eliminate emissions - in India and Asia where many of the population use them - this is a great application for fuel cells.

Scooters - In spite of their small size, many scooters are pollution powerhouses. Gas-powered scooters, especially those with two-stroke engines, produce tailpipe emissions at a rate disproportionate to their small size. These two-stroke scooters produce almost as much particulate matter and significantly more hydrocarbons and carbon monoxide as a heavy diesel truck. Fuel cell scooters running on hydrogen will eliminate emissions - in India and Asia where many of the population use them - this is a great application for fuel cells.

Forklifts/Materials Handling - Besides reducing emissions, fuel cell forklifts have potential to effectively lower total logistics cost since they require minimal refilling and significantly less maintenance than electric forklifts, whose batteries must be periodically charged, refilled with water, and replaced. Due to the frequent starting and stopping during use, electric forklifts also experience numerous interruptions in current input and output - fuel cells ensure constant power delivery and performance, eliminating the reduction in voltage output that occurs as batteries discharge.

Forklifts/Materials Handling - Besides reducing emissions, fuel cell forklifts have potential to effectively lower total logistics cost since they require minimal refilling and significantly less maintenance than electric forklifts, whose batteries must be periodically charged, refilled with water, and replaced. Due to the frequent starting and stopping during use, electric forklifts also experience numerous interruptions in current input and output - fuel cells ensure constant power delivery and performance, eliminating the reduction in voltage output that occurs as batteries discharge.

Auxiliary Power Units (APUs) - Today’s heavy-duty trucks are equipped with a large number of electrical appliances–from heaters and air conditioners to computers, televisions, stereos, even refrigerators and microwaves. To power these devices while the truck is parked, drivers often must idle the engine. The Department of Energy (DOE) has estimated the annual fuel and maintenance costs of idling a heavy-duty truck at over $1,800 and that using fuel cell APUs in Class 8 trucks would save 670 million gallons of diesel fuel per year and 4.64 million tons of CO2 per year.

Trains - Fuel cells are being developed for mining locomotives since they produce no emissions. An international consortium is developing the world’s largest fuel cell vehicle, a 109 metric-ton, 1 MW locomotive for military and commercial railway applications.

Trains - Fuel cells are being developed for mining locomotives since they produce no emissions. An international consortium is developing the world’s largest fuel cell vehicle, a 109 metric-ton, 1 MW locomotive for military and commercial railway applications.

Planes - Fuel cells are an attractive option for aviation since they produce zero or low emissions and make barely any noise. The military is especially interested in this application because of the low noise, low thermal signature and ability to attain high altitude. Companies like Boeing are heavily involved in developing a fuel cell plane.

Planes - Fuel cells are an attractive option for aviation since they produce zero or low emissions and make barely any noise. The military is especially interested in this application because of the low noise, low thermal signature and ability to attain high altitude. Companies like Boeing are heavily involved in developing a fuel cell plane.

Boats - For each liter of fuel consumed, the average outboard motor produces 140 times the hydrocarbonss produced by the average modern car. Fuel cell engines have higher energy efficiencies than combustion engines, and therefore offer better range and significantly reduced emissions. Iceland has committed to converting its vast fishing fleet to use fuel cells to provide auxiliary power by 2015 and, eventually, to provide primary power in its boats.

Boats - For each liter of fuel consumed, the average outboard motor produces 140 times the hydrocarbonss produced by the average modern car. Fuel cell engines have higher energy efficiencies than combustion engines, and therefore offer better range and significantly reduced emissions. Iceland has committed to converting its vast fishing fleet to use fuel cells to provide auxiliary power by 2015 and, eventually, to provide primary power in its boats.

Portable Power

Fuel cells can provide power where no electric grid is available, plus they are quiet, so using one instead of a loud, polluting generator at a campsite would not only save emissions, but it won't disturb nature, or your camping neighbors. Portable fuel cells are also being used in emergency backup power situations and military applications. They are much lighter than batteries and last a lot longer, especially imporant to soldiers carrying heavy equipment in the field.

Fuel cells can provide power where no electric grid is available, plus they are quiet, so using one instead of a loud, polluting generator at a campsite would not only save emissions, but it won't disturb nature, or your camping neighbors. Portable fuel cells are also being used in emergency backup power situations and military applications. They are much lighter than batteries and last a lot longer, especially imporant to soldiers carrying heavy equipment in the field.

Micro Power

Consumer Electronics- Fuel cells will change the telecommuting world, powering cellular phones, laptops and palm pilots hours longer than batteries. Companies have already demonstrated fuel cells that can power cell phones for 30 days with out recharging and laptops for 20 hours. Other applications for micro fuel cells include pagers, video recorders, portable power tools, and low power remote devices such as hearing aids, smoke detectors, burglar alarms, hotel locks and meter readers. These miniature fuel cells generally run on methanol, an inexpensive wood alcohol also used in windshield wiper fluid.

Consumer Electronics- Fuel cells will change the telecommuting world, powering cellular phones, laptops and palm pilots hours longer than batteries. Companies have already demonstrated fuel cells that can power cell phones for 30 days with out recharging and laptops for 20 hours. Other applications for micro fuel cells include pagers, video recorders, portable power tools, and low power remote devices such as hearing aids, smoke detectors, burglar alarms, hotel locks and meter readers. These miniature fuel cells generally run on methanol, an inexpensive wood alcohol also used in windshield wiper fluid.

http://www.fuelcells.org/basics/apps.html

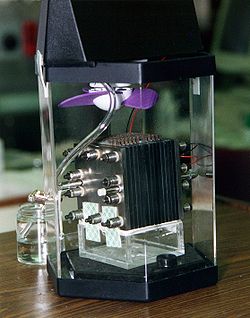

Most fuel cells designed for use in vehicles produce less than 1.16 volts of electricity-far from enough to power a vehicle. Therefore, multiple cells must be assembled into a fuel cell stack. The potential power generated by a fuel cell stack depends on the number and size of the individual fuel cells that comprise the stack and the surface area of the PEM.

Most fuel cells designed for use in vehicles produce less than 1.16 volts of electricity-far from enough to power a vehicle. Therefore, multiple cells must be assembled into a fuel cell stack. The potential power generated by a fuel cell stack depends on the number and size of the individual fuel cells that comprise the stack and the surface area of the PEM. Before FCVs make it to your local auto dealer, significant research and development is required to

Before FCVs make it to your local auto dealer, significant research and development is required to

Fuel cell power generation systems in operation today achieve 40 percent fuel-to-electricity efficiency utilizing hydrocarbon fuels. Since fuel cells operate silently, they reduce noise pollution as well as air pollution and when the fuel cell is sited near the point of use, its waste heat can be captured for beneficial purposes (cogeneration). In large-scale building systems, these fuel cell cogeneration systems can reduce facility energy service costs by 20% to 40% over conventional energy service and increase efficiency to

Fuel cell power generation systems in operation today achieve 40 percent fuel-to-electricity efficiency utilizing hydrocarbon fuels. Since fuel cells operate silently, they reduce noise pollution as well as air pollution and when the fuel cell is sited near the point of use, its waste heat can be captured for beneficial purposes (cogeneration). In large-scale building systems, these fuel cell cogeneration systems can reduce facility energy service costs by 20% to 40% over conventional energy service and increase efficiency to  Landfills/Wastewater Treatment Plants/Breweries

Landfills/Wastewater Treatment Plants/Breweries Cars

Cars Buses

Buses Scooters

Scooters Forklifts/Materials Handling -

Forklifts/Materials Handling -  Trains -

Trains -  Planes -

Planes -  Boats -

Boats -  Fuel cells can provide power where no electric grid is available, plus they are quiet, so using one instead of a loud, polluting generator at a campsite would not only save emissions, but it won't disturb nature, or your camping neighbors. Portable fuel cells are also being used in emergency backup power situations and military applications. They are much lighter than batteries and last a lot longer, especially imporant to soldiers carrying heavy equipment in the field.

Fuel cells can provide power where no electric grid is available, plus they are quiet, so using one instead of a loud, polluting generator at a campsite would not only save emissions, but it won't disturb nature, or your camping neighbors. Portable fuel cells are also being used in emergency backup power situations and military applications. They are much lighter than batteries and last a lot longer, especially imporant to soldiers carrying heavy equipment in the field.